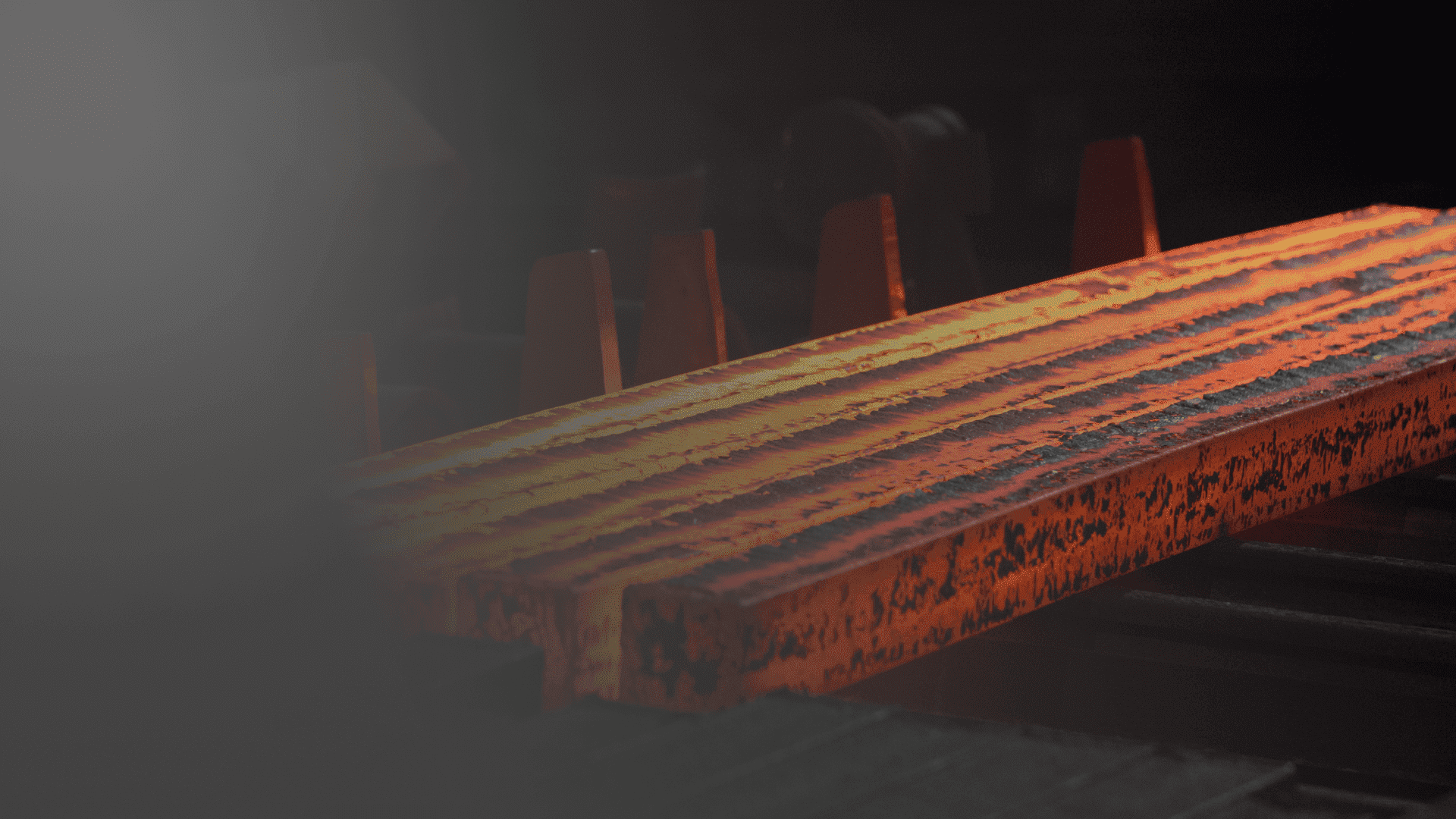

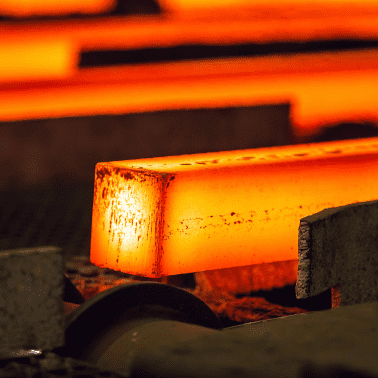

Strength

you can Trust

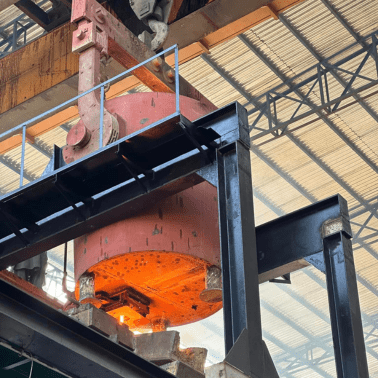

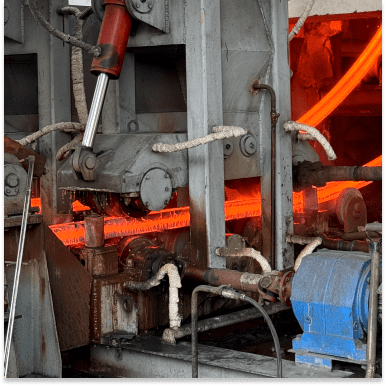

Build the foundation of structures that last with our Grade-60 & Grade-80 Deformed Steel Bars. Trust us to deliver durability, reliability, and quality in every beam. Your vision, our steel, a partnership for enduring success. Rasheed Steel is proud to offer international standard steel in Karachi, recognized among the best steel companies in Pakistan for our commitment to excellence, precision manufacturing, and unwavering quality standards.

info@rasheedsteel.com

info@rasheedsteel.com +92 300 254 3351

+92 300 254 3351